A supreme bridge can be defined as

a bridge that can support a large amount of weight at a low cost. That was the goal for this class. Our job was to build the best bridge possible

using K’Nex pieces. A truss is a

triangular joint that disperses weight.

Most bridges today are built with some sort of truss system. Each week we were given a different

assignment regarding bridges. Throughout

this course we would use software, online resources, pencil and paper, K’Nex

and our minds to design a bridge. Westpoint Bridge Designer is a popular

bridge-design program that allows the user to create their own bridge and test

it. The program displays results in the form of compression and tension forces

acting on the designed bridge. Bridge Designer was also used. This program focuses heavily on forces of

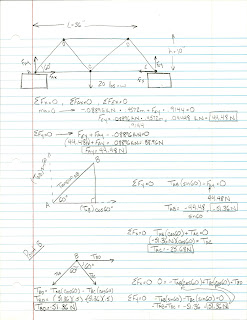

tension and compression acting on a bridge that the user sketches. One could also analyze forces acting on a

bridge using the “Methods of Joints”.

This process requires the use of physics to calculate forces acting on

joints. The first bridge that needed to

be built had to be at least two feet long.

This allowed us to get in some good bridge building experience before we

started on our final design. While

building, it was suggested that cost be kept in mind because the cost to weight

ratio is what the final bridge’s effectiveness will be determined by. After the two-foot bridge was built, the next

task was to construct a three-foot bridge.

This time, the bridge had to have a two-by-three inch hole running through

the middle. This constraint was

implemented to simulate the construction of an actual bridge in which a

passageway for transportation was necessary. As the term went on, each group

member was responsible for posting entries on the team blog weekly. These posts would answer a question determined

by the professor each week and recap what had happened in or out of class during

the previous week.

From the

beginning, the goal was to build a strong bridge and brainstorm ways to make it

less expensive. The team favored this

approach because there was always a way to make the bridge support more weight

and there were always ways to make the bridge less expensive. This was not the most efficient approach

because supporting the most weight does not always result in the best

bridge. The best way to build a bridge

is to consider factors such as cost and strength, in the design planning. To achieve success other small goals were

set. The team planned on meeting weekly to

discuss our plans while moving further.

This was a good idea because it gave each member more time to

brainstorm. Another goal was to listen

to and consider every idea. When conflicting

ideas arose, compromising is always the most effective solution. Every goal that was established early in the

course was met even though the final bridge outcome was somewhat of a

disappointment. The goal to build the

strongest bridge possible and disregard cost was the only goal that was altered

in the building process. This method was

abandoned because it would severely alter the cost-weight ratio and one design

mistake could result in an unfavorable, high ratio. Our first bride design was

ridiculously expensive. More

specifically it was the most expensive in the class. This is the point where our goal

changed. For the second bridge design,

which was the three-foot design, we had made cost efficiency a main priority

along with strength. The role of

individual assignments was very helpful when compiling the final design. These assignments made the group come up with

as many bridge designs as possible so that best design could be chosen. These assignments also help us get a better individual

understanding of bridge design. Westpoint Bridge Designer helped each

member achieve a better understanding of what designs worked the most

efficiently and which ones did not. The

force analysis and calculations brought to attention where significant force

was being applied the most and where it was being applied the least. The program also challenged each member to

try and make an inexpensive bridge while also maintaining the bridge’s safety. When the truss analysis was carried out, it

again revealed areas on the bridge supporting large amounts of tension and

compression. In addition to using the

program, each member also carried out calculations done by hand. Each member’s individual designs produced the

widest range of ideas. This was helpful

because the team was able to see which design was the most effective, then

improving on the chosen design. After testing

the original bridge design, the structure bowed and the bridge failed. When it was time to build the final bridge, the

two most important objectives in mind were cost and failing weight. The original bridge was incredibly expensive

due to the large amount of pieces used.

To lower price, the team used longer members and fewer gusset plates. The

three-foot-long final bridge ended up costing as much as the original two-foot

bridge. To avoid the bridge failing due

to bowing to the side, additional trusses were placed in the center of the

bridge. At first when the final bridge

was tested, it did not hold as much weight as was hoped. As a result, an additional truss section was

added to the top of the bridge for added stability. This change resulted in the bridge’s ability

to support another ten pounds. The final

design resembled a series of attached cubes with a top truss section. The sides had trusses resembling X’s, held

together by members that were perpendicular to the sides and trusses in the middle. The predicted load at failure for the final

bridge was about forty pounds.

|

| Figure 1: Truss Analysis |

|

| Figure 2: Bridge Designer |

|

| Figure 3: Westpoint Bridge Design |

The three-foot bridge design was

approached in a similar way as the two-foot bridge, except for minor changes to

reduce cost. All grooved gusset plates were removed to significantly reduce

overall cost. The design began as a simple truss bridge with X-shaped supports

on the sides and an over truss section for added support. The bridge continued

to be less stable than desired. Because of this, more pieces were added to the

center. These added supports resulted in the doubling of the overall amount of

weight the bridge was able to support.

Bill

of Materials - Knex Pieces

|

|||||||

Part

Number

|

Description

|

Unit

Cost ($)

|

Nr. of

Parts

|

Cost

($)

|

|||

1

|

1.25"

long chord

|

$500

|

56

|

$28,000

|

|||

2

|

2.125"

long chord

|

$1,000

|

108

|

$108,000

|

|||

3

|

3.375"

long chord

|

$1,500

|

80

|

$120,000

|

|||

4

|

5"

long chord

|

$2,000

|

10

|

$20,000

|

|||

5

|

7.5"

long chord

|

$3,000

|

0

|

$0

|

|||

6

|

chord

splice

|

$1,000

|

0

|

$0

|

|||

7

|

45

degree gusset plate

|

$1,000

|

0

|

$0

|

|||

8

|

90

degree gusset plate

|

$1,000

|

0

|

$0

|

|||

9

|

135

degree gusset plate

|

$1,000

|

0

|

$0

|

|||

10

|

180

degree gusset plate

|

$1,000

|

108

|

$108,000

|

|||

11

|

180

degree grooved gusset plate

|

$2,000

|

0

|

$0

|

|||

12

|

360

degree gusset plate

|

$1,000

|

0

|

$0

|

|||

13

|

360

degree grooved gusset plate

|

$2,000

|

0

|

$0

|

|||

Total Cost

|

$384,000

|

||||||

|

| Figure 4: Bridge Sketch |

|

| Figure 5: Final Design |

The bridge failed around 31 pounds.

Instead of exploding into thousands of pieces, the bridge bowed out to the

side. The bridge broke on the right side under the raised truss section, just

as predicted. In a real life situation this would be preferred because bridge maintenance

would be easier. Inspectors would know where to look if the bridge was failing.

|

| Figure 6: Breaking Point |

|

| Figure 6.1: Breaking Point |

After testing the final, three-foot

bridge, it was determined that the bridge was able to support 42.3 pounds. The

maximum amount of weight the bridge could support was tested by suspending a

bucket from the center of the bridge and gradually filling it with sand. This

is a far better result than what was originally predicted. During testing, the

bridge failed on the right side directly beneath where the additional truss

section ends. Calculations were made for find the compression and tension

forces acting on the bridge when weight is added. These calculations were used

to predict where the bridge would most likely fail. In conclusion, the maximum

weight of 42.3 pounds was a very successful, unexpected result.

If we were

to design another bridge in the future, we would not make any major changes. We

are very happy with our final bridge result. However, if we wanted to save

money and reduce the overall cost, we could remove some members of the bridge

that are not as essential to the bridge’s strength. Another way to cut down on

the bridge’s overall cost would be to remove some gusset plates. Our bridge has

a lot of joints, I we took out some of these gusset plates, our overall price

would be significantly less but so would the amount of weight the bridge can

support. If our goal were to increase the amount of weight the bridge is able

to support, our main focus would be to add more members. With more members on

the bridge, the weight it is supporting will be dispersed among more supports,

reducing the total amount of tension and compression on each support.

No comments:

Post a Comment